Ever wonder how a stop sign is made?

Now you don't have to! Here is a breakdown of how we make our Stop signs.

First, let's start with the basics.

1. SIZES

Highway Traffic Supply offers STOP signs in many different sizes. But, some of the most common are as follows:

- 18”x18”

- 24”x24”

- 30”x30”

- 36”x36”

2. REFLECTIVITY GRADES

We also offer this sign in different Reflective grades:

- 3M™ Engineer Grade 3430

- 3M™ High Intensity 3930

- 3M™ Diamond Grade 3990

For a more comprehensive guide to reflective sheeting types, please click here.

Even though these signs are different sizes and grades of reflectivity, they, are all produced using the same method.

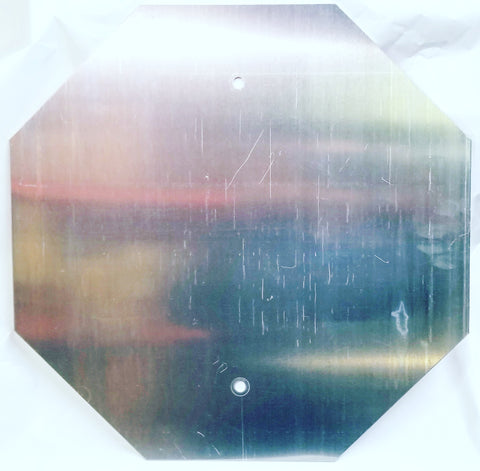

3. SUBSTRATE

Although you may be able to find Stop signs online and in stores made of other materials, such as heavy-duty plastic, we make all of ours on aluminum. We do this because our signs are manufactured to meet MUTCD (Manual on Uniform Traffic Control Devices) standards. We use high-quality, produced in the U.S.A., .080” thick anodized aluminum. The anodized coating prevents corrosion and stabilizes the aluminum for the best adhesion of the Reflective Sheeting.

The Aluminum is wiped clean to prevent dust, or any other contaminates with interfering with the reflective sheeting application.

4. APPLY THE REFLECTIVE SHEETING

The next step is the application of the reflective sheeting. This process is the same for all 3M™ reflective products.

We use an automated laminator which applies the sheeting at 80psi to guarantees flawless adhesion.

Once the 3M™ reflective sheeting is applied, the excess material is removed by one of our skilled technicians.

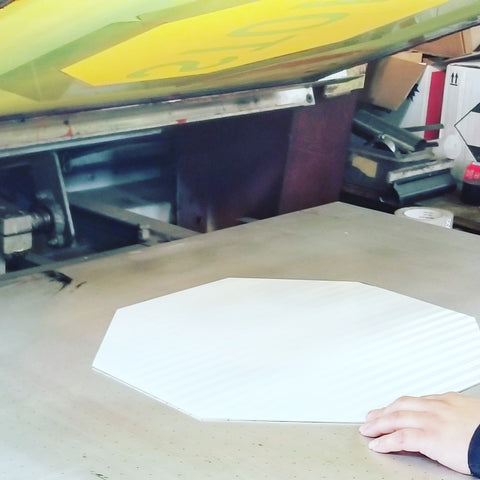

5. PREPARING FOR THE LEGEND

The final step is the application of the legend. As seen, the aluminum is covered with the white reflective sheeting. Before the legend is applied the blank is wiped to prevent contamination.

6. APPLYING THE LEGEND (SILK-SCREENING)

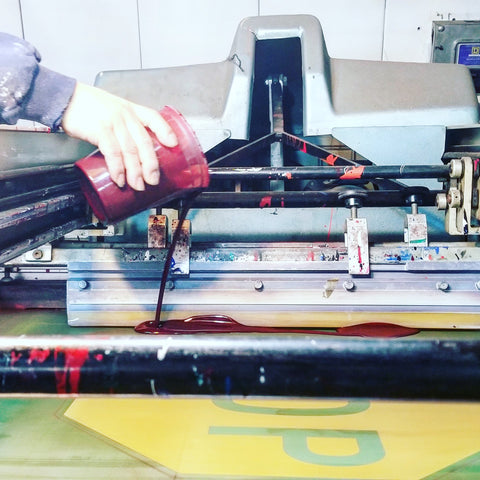

Next, we apply the legend. This is accomplished with silk screening. The STOP image has been stenciled into silk mesh to create a negative image.

As with our other printing materials, the inks we use at Highway Traffic Supply are high-quality 3M™ inks and thinners designed explicitly for use on signs. These are formulated for indoor and outdoor use and is backed by the 3M™ Limited 10 Year Product Warranty.

The screen containing the image is loaded into the automated press.

Our technician aligns and registers the blank for proper boarder distance and centering.

Once everything is aligned and centered the technician loads the screen with the ink.

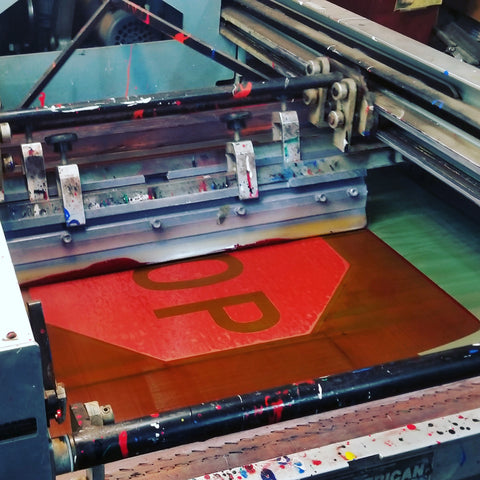

The silkscreen press initiates. The press moves the flood bar to the back of the screen, loading the image with ink. The squeegee then moves forward transferring the ink onto the reflective sheeting. Finally, the press lifts so the sign may be removed from the machine.

7. DRYING

The finished sign is then placed in a drying rank for 12 to 24 hours for drying and curing.

We hope you have a better understanding of how Stop signs are made. Remember, it can be a lot of work, but if you don't have the time to make one on your own, you can always let us do it for you!

Talk to you again soon!

Thanks for reading! Use code BLOG2019 for 15%off your next order until March 1st 2019!